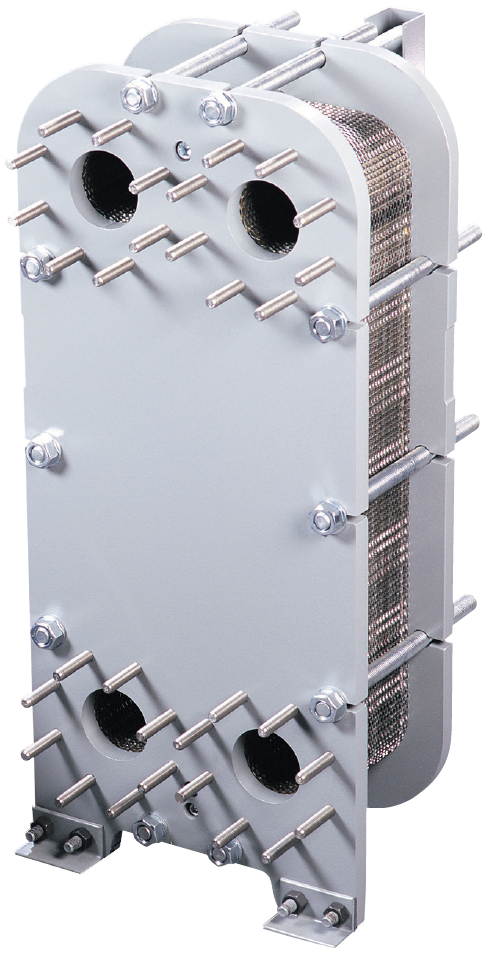

Description

Materials:

304 and 316 Stainless Steel, Titanium, SMO 254, Hastelloy, Incolloy, AL6XN Plates. Gaskets in Nitrile, EPDM, Viton, high temperature EPDM and high temperature Nitrile. Other materials available upon request.

Applications:

Include but not limited to: heat recovery, equipment heating/cooling, make-up water preheating, chemical processes, central water, stator water, oil, auxiliary water, jacket water, drilling fluid. Double wall plates to reduce the possibility of fluids intermixing. Semi-welded for refrigeration or where reducing the fluid’s contact with elastomers is desired. Free Flow is ideal for pulp and paper or ethanol/biodiesel processes.

Features and Benefits:

- Higher surface area to volume ratios than conventional shell and tube heat exchangers

- Superior heat transfer coefficients compared to shell and tube heat exchangers

- Offers “true” countercurrent flow, which maximizes the mean temperature difference between fluids