Description

Features and Benefits

- Closed-loop collector tube floats on water surface

- Collector tube performance is unaffected by any floating debris

- Tube easily floats up or down to adjust to changing water level

- Gyrating action of collector tube breaks up oil crusts

- Virtually maintenance-free operation

- Unique anti-clogging design

- Cast metal housing and structural members

- High performance, quiet-running motor

- Can operate unattended 24/7

- Up to 30-year operating life

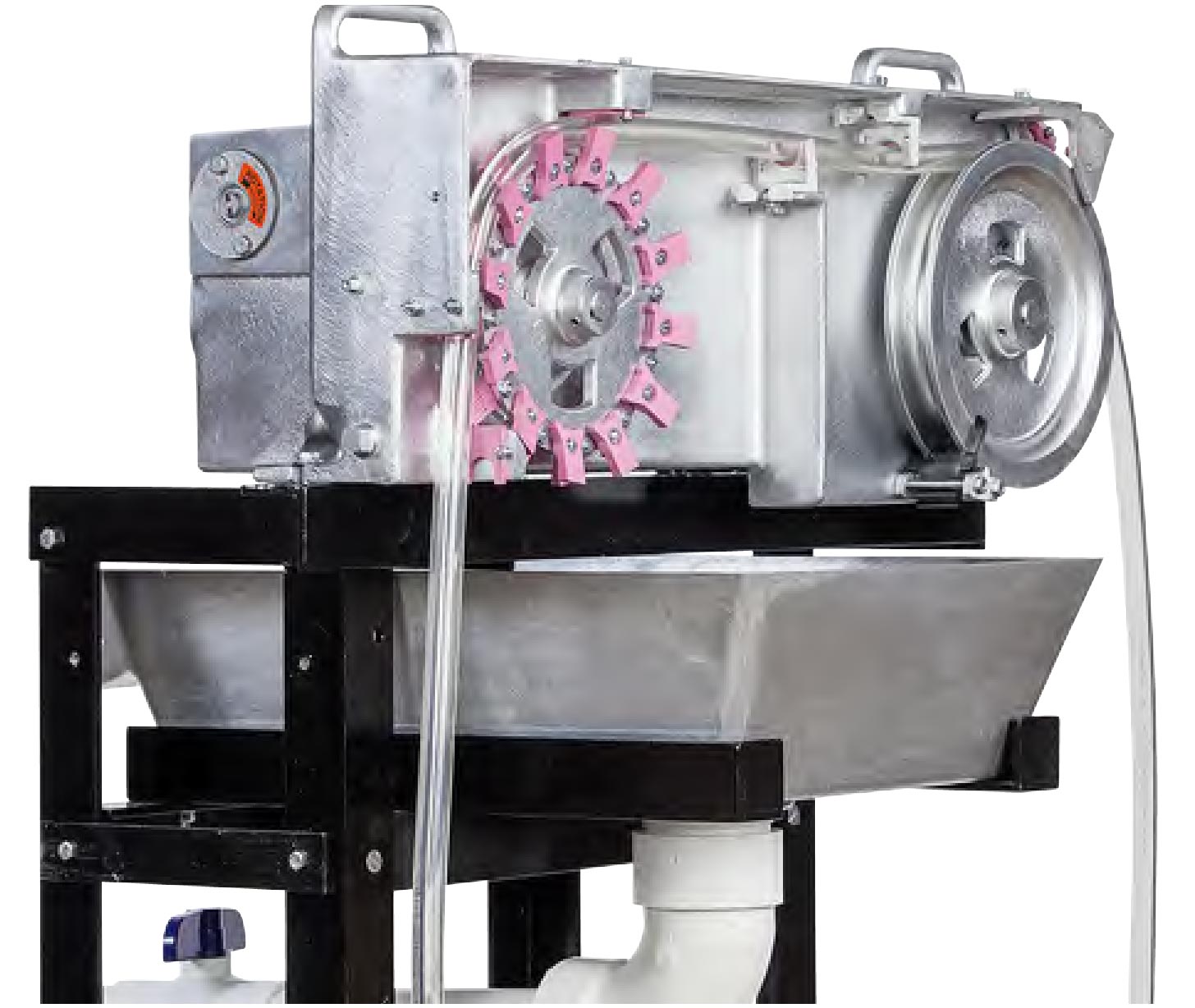

How the Model 6V Works

The Oil Skimmers Model 6V Brill® waste oil recovery system removes oil from water using a specially formulated collector tube:

- Oil adheres to the outside of the floating closed-loop tube as it is drawn across the surface of the contaminated water and into the oil skimmer

- Unlike other types of skimmer skimmers, which can get clogged by floating debris, the tube type skimmer snakes over and around floating debris, adjusting automatically to changing water levels

- The tube is then drawn up into the oil skimmer and through scrapers that remove the oil

- The tube returns to the water surface to collect more oil

- Recovered oil flows into a collection container

The Expertly Crafted, Customizable Oil Separation Solution

Engineered for headache-free operation, the external parts of the Oil Skimmers Model 6V Brill® unit – the drive wheel fingers, scrapers, and pressure blocks – are made of high abrasion-resistant ceramic. Gearing is engineered to require minimal power and maintenance, and sealed in a cast housing to protect them from conditions found in environments where skimmers often are placed.

Thoughtful design and durable construction ensure the Model 6V Brill® system an operational life span of 25 to 30 years. Many units have been in service for more than 30 years and are still going strong.

The Oil Skimmers Model 6V Brill® waste oil recovery system has been designed to operate continually and unattended as it separates animal, vegetable, and petroleum-based oils, fats, and greases floating on the surface of industrial process water and wastewater.

Pre-engineered mounting systems increase the 6V’s versatility and flexibility. They simplify placement of the system on pits, sumps, ponds, and open or closed tanks, thus eliminating costly development and fabrication of creating your own mount.

With experience in over 35,000 applications, our experienced representatives are available to survey your oil removal needs and provide a complete oil removal system to meet even the most challenging oil on water problem.

Typical Applications

Model 6V oil skimmers are at work in thousands of applications worldwide. A sampling includes:

- Machining and Metalworking

- Wastewater Treatment

- Saltwater Disposal Sites

- Heat Treating

- Steel Production

- Chemical Processing

- Poultry Processing

- Metal Processing

- Automotive Parts Manufacturing

- Food Processing

- Fuel Distribution

- Metal Office Furniture

- Power Generation

- Heavy Equipment Wash

- Tank and Truck Wash Facilities

- And any application where waste oil needs removed from water or coolant