Description

The shell is of welded construction. A carbon steel shell will be welded to carbon steel inner tubesheets on both ends, which in turn are welded to 90/10 CuNi outer tubesheets. The outer tubes are roller expanded into the inner tubesheets. The inner tubes are roller expanded the full length of the outer tubes and into the outer tubesheets. The void space between the tubesheets on each end of the cooler are fitted with ¼” IPS vent and drain nipples to detect any tube leakage. The bonnets are one piece cast construction.

The EF(N) exchanger is capable of passing the high – impact shock test of MIL-C-901 Grade A, Class I, Type A and the vibration test of MIL-STD-167, Type I.

Application:

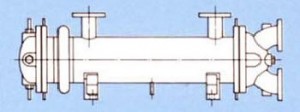

Straight tube, removable bundle, packed floating tubesheet heat exchanger

Features and Benefits

- Carbon steel or 90/10 Copper-Nickel shell

- Cast Bronze, Cast 70/30 Copper-Nickel, Fabricated 70/30 and 90/10 Copper Nickel Bonnets

- Admiralty, 90/10, 70/30 Copper-Nickel tube options

- Shellside and Tubeside Design Max 150 PSI – 250 Deg F. Special designs for higher pressures and temperatures