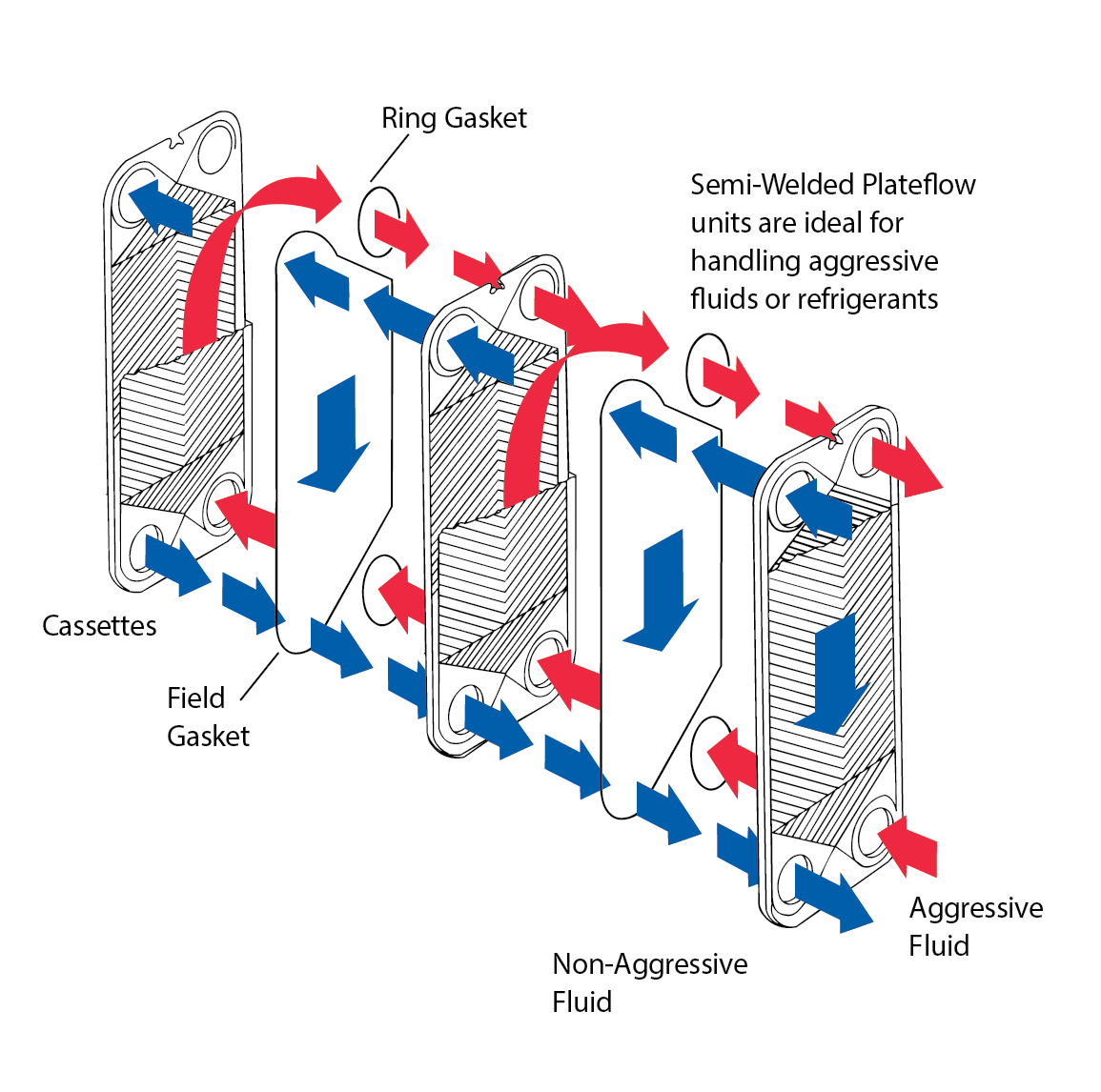

Description

Materials:

304 and 316 Stainless Steel, Titanium, SMO 254, Hastelloy, Incolloy, AL6XN Plates. Field gaskets in Nitrile, EPDM, Viton, high temperature EPDM and high temperature Nitrile. Ring gaskets in Nitrile, EPDM, Chloroprene, PTFE coated, and Viton. Other materials upon request.

Applications:

For close temperature approach of fluids for heat recovery applications. Semi-welded Plateflow exceptional for refrigerant, aggressive chemical, or any applications where reducing the fluid’s contact with elastomers is desired.

Features and Benefits:

- Higher surface area to volume ratios than conventional shell and tube heat exchangers

- Superior heat transfer coefficients compared to shell and tube heat exchangers

- Offers “true” countercurrent flow, which maximizes the mean temperature difference between fluids