Description

Automation Minimizes Disposable Waste and Labor Costs

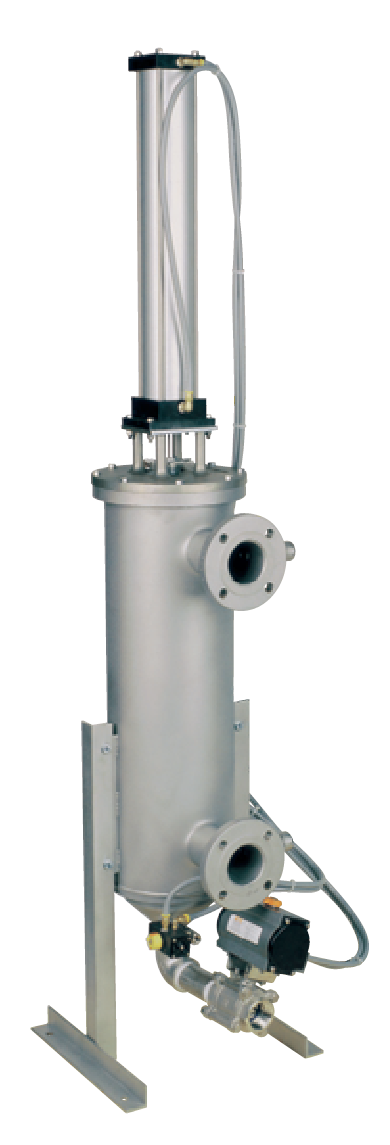

Highlights of the DCF Mechanically Cleaned Filter

- Elimination or reduction in disposable filter bags and cartridges for reduced operator handling inventory costs and landfill waste

- Reduction in product loss, more thorough contaminant purge in a highly concentrated waste stream

- Virtually maintenance free, near 100% uptime

- Compact design, lower capital cost to fit most installations

- Stainless steel screens from 15 micron slots to 1/4″ perforations to handle a wide range of filtration needs

- Available with UHMWPE, Urethane-, Teflon, or Kynar-Cleaning Discs

The DCF is the best self-cleaning filtration solution for minimizing product loss in high-value and/or high viscosity fluids.

- DCF-800-TWSI-GA001 – Single Filter W Twin Actuator Unit Drawing

- DCF-800 Parts

- DCF-800-IOM

- DCF-1600-TWSI-GA002- Single W Twin Actuator Design Unit Drawing

- DCF-1600-X-PA002 Parts

- DCF-1600-IOM